HYDRAULIC TESTING MACHINE

HYDRAULIC TESTING MACHINE

UNIVERSAL TESTING MACHINE

We “Unique Hydraulic” provides Universal Testing Machine (UTM) which is a hydraulic-electric machine used in engineering where main mechanical properties of given specimen of a construction material are being tested.

The UTM has two major parts

Host machine- it consist of two parts tensile and compression section where tests like tensile and compression test is conducted. The tensile section is the upper section of host machine and the lower part is compression section where compressive or flexural test is conducted.

Machine controller- It is that part of machine which process, store and display the data of material being tested. This machine also provides graph of the input parameter using computer. The printer can print the test report.

Availability and Specification

Main specifications

|

Model |

UH-100/300D |

UH-600D |

UH-1000D |

|||

|

Max load (kN) |

100/300 |

600 |

1000 |

|||

|

Structure |

6 column |

|||||

|

Control way |

loading process manual control,computer automatic data dealing |

|||||

|

Load resolution |

1/300000 |

|||||

|

Deformation Measurement Range |

2%~100%FS |

|||||

|

Deformation accuracy |

≤±1%/± 0.5% |

|||||

|

Displacement resolution |

0.01mm |

|||||

|

Displacement error |

≤±0.5% |

|||||

|

Max.piston stroke |

250mm |

|||||

|

Max. tension test space |

650mm (can customize) |

|||||

|

Max.Compression Test Space |

500mm (can customize) |

|||||

|

Oil cylinder moving speed |

140 |

90 |

50 |

|||

|

Crosshead moving speed |

200 |

150 |

120 |

|||

|

Effective space between columns (mm) |

430 |

475 |

525 |

|||

|

Round specimen clamping range |

Φ10-Φ32mm |

Φ13-Φ40mm |

Φ13-Φ40mm |

|||

|

Flat specimen clamping range |

0-15mm |

|||||

|

Clamping method |

Hydraulic clamp |

|||||

|

Clamp height |

70mm |

90mm |

90mm |

|||

|

Clamping width |

75mm |

80mm |

80mm |

|||

|

Compression plate size |

φ160mm |

|||||

|

Bending roller distance |

450mm |

|||||

|

Width of bending rollers |

120mm |

|||||

|

Power supply |

3-phase,AC380V, 50Hz(can be customized) |

|||||

APPLICATIONS

- In UTM we test the mechanical properties like tensile strength, compression strength, bending capacity and some other physical properties of materials. The usual property of UTM is pulling, compressing and bending or stretching until material get break.

- These different tests determine the quality of material as well as how suitable it is for particular use. The UTM is primarily used by the laboratory that manufactures or mould plastics.

- It is widely used in different steel works, engineering areas, quality control department, Universities and institutes as well as other areas and works.

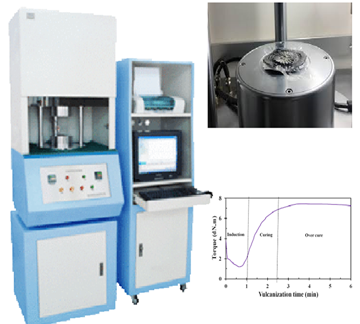

The MDR one Moving Die Rheometer (MDR) is a reliable, accurate, and easy-to-operate rotorless curemeter perfect for routine and standards-driven testing of rubber curing. The MDR one is configured for measuring curing profiles of rubber compounds under isothermal and non-isothermal test conditions at constant strain and frequency.The MDR one employs sealed biconical dies meeting all relevant ASTM, ISO, and DIN standards.The unique design includes an ultra-rigid test frame, direct drive motor, precision temperature control with optional cooling, available Autosampler, and intuitive Scarabaeus Control and Analysis software making it the ideal platform for QC or R&D environments.

MOVING DIE RHEOMETER

Our company is involved in manufacturing and supplying a wide array of Bridge Bearing Testing machine ranging from 1000tons to 3000 tons.

FEATURES

- Provide machine both in Pillar type and Column type.

- Vertical clamping force range from 1000 tons to 3000 tons and horizontal clamping force vary from 500 tons to 2000 tons.

- User-friendly relay logic/PLC/HMI controls with advanced diagnostic capabilities for process optimisation and sequence setting.

- Hydraulic system consists of double vane pump, relief valve, flow controls valve, and solenoid operated direction control valves. All controls are fitted on single manifold to avoid complicated tubing.